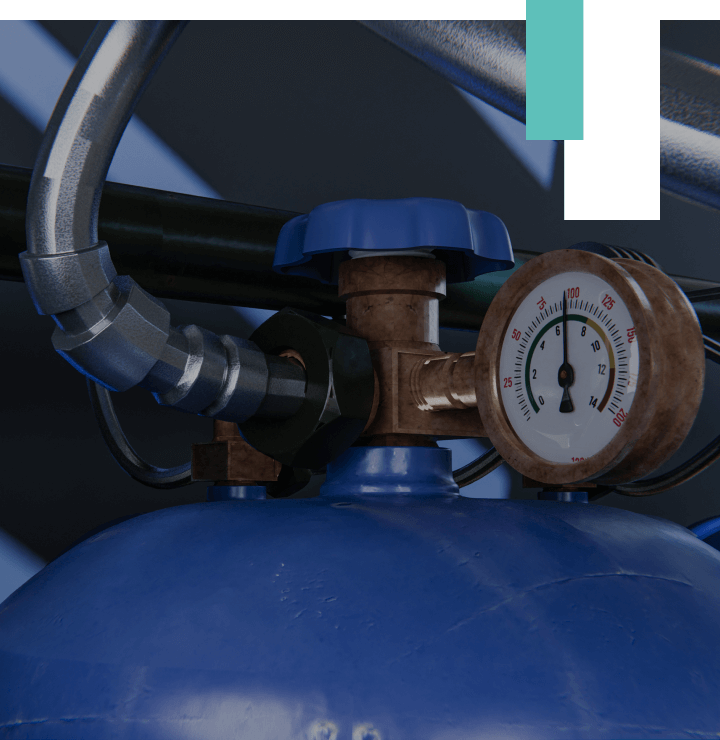

Saini Flow Control offers a wide range of versatile flow control systems that provide custom-engineered solutions for various industries. With a proven track record of excellence and innovation spanning over four years, Saini Flow Control offers engineered solutions for key sectors such as Oil, Gas, Power, Petrochemicals, Chemicals, Fertilizers, Pharmaceuticals, Paper, Sugar, and Steel Industries. Our manufacturing infrastructure includes a versatile forging unit, CNC Machining workshop, and Assembly unit.